Aerosol Crimping Machine

Aerosol Crimping Machine Specification

- Surface Finish

- Smooth, Polished

- Shape

- Hand Held, Cylindrical Head

- Noise Level

- Low (manual operation, no motor)

- Drive Type

- Manual Lever Operated

- Diameter

- Crimp Head Diameter: 25.4 mm (1 inch)

- Lubricating System

- Manual Lubrication if Required

- Usage & Applications

- Crimping aerosol cans for sealing purposes in laboratories, cosmetic, pharmaceutical, and chemical industries.

- Product Type

- Aerosol Crimping Machine

- Material

- Stainless Steel

- Technology

- Mechanical/Manual Operation

- Power Source

- Manual

- Pressure

- Hand Operated, No Compressed Air Required

- Surface Treatment

- Polished

- Dimension (L*W*H)

- 180 mm 60 mm 40 mm (Approx.)

- Weight

- 1.2 kg (Approx.)

- Color

- Silver

- Sealing Type

- Radial crimp for airtight sealing

- Operator Skill

- No special training required

- Replacement Parts

- Available upon request

- Maintenance

- Easy disassembly for cleaning and servicing

- Operating Temperature

- Ambient (Suitable for normal room environment)

- Packaging

- Supplied in protective case

- Handle Type

- Ergonomic grip for comfortable handling

- Lead Time

- Immediate or As per availability

Aerosol Crimping Machine Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 6 Week

- Main Domestic Market

- All India

About Aerosol Crimping Machine

Owing to our advanced equipment and out-of-the-box methodology, we are able to manufacture, supply and export Industrial Aerosol Crimping Machine . Made of superb quality raw materials, these products do not falter at time of operation. We have hired a team of diligent quality analyzers, which is involved in checking of these machines so as to ensure their high and hassle free performance. These products are used in the automobile industry for varied crimping applications. Industrial Aerosol Crimping Machine is highly appreciated in the global arena for its longer service life and high strength.

Reliable Airtight Sealing

Using a radial crimping method, this machine ensures every aerosol can is sealed securely for maximum product integrity. The robust, stainless steel construction and cylindrical crimp head (25.4 mm diameter) are designed to deliver consistent, leak-proof joints. Its application spans a broad array of industries, including laboratories, cosmetics, pharmaceuticals, and chemicals.

Effortless and Ergonomic Operation

Engineered for manual operation, the devices ergonomic grip minimizes user fatigue while enabling precise control. Operating it doesnt require special training, making it suitable for both new and experienced personnel. With no need for compressed air or electricity, this crimping machine delivers a reliable sealing solution in virtually any environment.

Easy Maintenance and Portability

Maintenance is straightforward due to the simple disassembly, facilitating thorough cleaning and servicing when needed. The unit is supplied in a protective case, ensuring safe storage and effortless portability between worksites or laboratories. Replacement parts can be sourced readily, supporting long-term performance and cost-effectiveness.

FAQs of Aerosol Crimping Machine:

Q: How does the aerosol crimping machine ensure an airtight seal?

A: The machine uses a radial crimping mechanism that applies uniform pressure around the cans neck, effectively sealing the aerosol can to prevent leaks and maintain product integrity.Q: What industries commonly use this crimping machine?

A: This device is widely adopted in laboratories as well as the cosmetic, pharmaceutical, and chemical industries for sealing aerosol cans efficiently and safely.Q: When is maintenance required, and how is it performed?

A: Maintenance is needed periodically or if residue build-up is noticed. The crimping machine can be easily disassembled for cleaning and manual lubrication if required, ensuring optimal functionality.Q: Where should the machine be operated for best results?

A: The unit is designed for use in an ambient room environment. No special conditions or power sources are required, making it suitable for standard lab or industrial settings.Q: What advantages does the ergonomic handle offer?

A: The ergonomic grip reduces user fatigue and enhances handling comfort, allowing the operator to perform consistent crimps over extended periods with minimal strain.Q: Is special training needed to operate the device?

A: No special training is required. The manual, lever-operated design is straightforward, ensuring easy usage for personnel of varying experience levels.Q: How can I obtain replacement parts for this machine?

A: Replacement parts are available upon request from the manufacturer, exporter, or supplier, ensuring quick turnaround and continued operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aerosol Crimping Machine Category

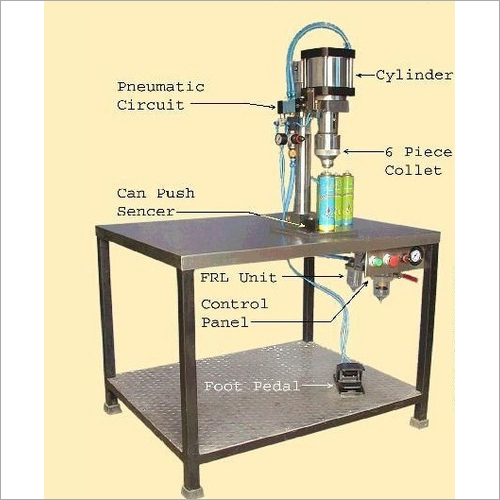

Semi Automatic Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Surface Finish : Smooth Painted

Power Source : Other, Electric

Noise Level : Low Noise (<70 dB)

Technology : Other, SemiAutomatic

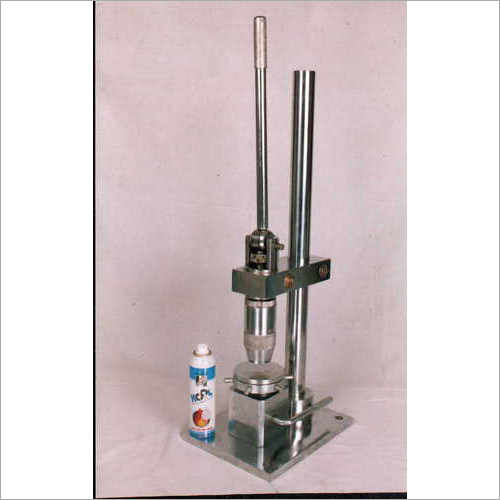

Crimping Machine (Hand Operated-Bottle)

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Surface Finish : Smooth/Polished

Power Source : Other, Manual

Noise Level : Low

Technology : Other, Mechanical Lever Mechanism

Hand Operated Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Surface Finish : Smooth

Power Source : Other, Manual

Noise Level : Low

Technology : Other, Manual Mechanical Operation

Aerosol Can Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Surface Finish : Smooth

Power Source : Other, Electric

Noise Level : <75 dB

Technology : Other, Manual / Pneumatic Crimping

Send Inquiry

Send Inquiry