Hand Operated Crimping Machine

Hand Operated Crimping Machine Specification

- Capacity

- Up to 10 mm wire cross-section

- Usage & Applications

- Crimping terminals, connectors, lugs in electrical and industrial applications

- Drive Type

- Hand Operated

- Features

- Portable, Easy to Operate, Durable Construction, Non-slip Handle

- Surface Finish

- Smooth

- Size

- Standard

- Shape

- Rectangular Base with Lever Mechanism

- Noise Level

- Low

- Diameter

- Applicable for terminal sizes up to 10 mm

- Lubricating System

- Manual lubrication required

- Product Type

- Hand Operated Crimping Machine

- Material

- Mild Steel

- Technology

- Manual Mechanical Operation

- Power Source

- Manual

- Power

- Not Applicable (Manual)

- Pressure

- Manual Pressure

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- Approx. 350 mm x 150 mm x 250 mm

- Weight

- Around 8 kg

- Color

- Blue & Silver

- Operating Temperature

- 5°C to 50°C

- Jaw Material

- Hardened Alloy Steel

- Maintenance

- Periodic cleaning and lubrication required

- Safety

- Integrated Safety Lock

- Crimping Range

- 0.5 mm² to 10 mm²

- Handle Type

- Ergonomic Rubber Grip

- Application Industries

- Automotive, Electrical, Construction, Maintenance

- Portability

- Hand Carry

- Storage

- Can be stored in compact toolboxes

Hand Operated Crimping Machine Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 6 Week

About Hand Operated Crimping Machine

A Hand Operated Crimping Machine is offered by us that is a device for conjoining two pieces of metal fitting with sections of rigid, flexible hose and tubing by deforming one or both of them to hold each other and stick together, as seen when fixing a connector to the end of a cable. It is a device for conjoining two pieces of metal fitting with sections of rigid, flexible hose and tubing by deforming one or both of them. Hand Operated Crimping Machine is very effective and useful.Versatile Crimping Made Easy

Engineered for a wide crimping range, this machine seamlessly handles wire and terminal sizes up to 10 mm2. Its rectangular base and lever mechanism offer stable operation across multiple industries, including automotive, electrical, and construction. Whether in workshops or on-site locations, its portability and compact dimensions make it an ideal choice for professionals who need reliability and efficiency.

Built for Safety and Comfort

Safety and user comfort are at the forefront of this design. The integrated safety lock prevents accidental operation, while the ergonomic rubber handle reduces hand fatigue. Its robust construction and powder-coated finish enhance longevity, allowing for consistent use in demanding environments. The low noise level ensures a comfortable work setting without unnecessary disruption.

Simple Maintenance for Long-Term Reliability

This crimping machine is engineered for minimal upkeep. By performing periodic cleaning and manual lubrication, users can maintain smooth operation and extend the tool's life. Designed to fit into standard toolboxes, it's always ready for quick transport and deployment at any job site.

FAQ's of Hand Operated Crimping Machine:

Q: How do I operate the Hand Operated Crimping Machine safely?

A: To operate the crimping machine, secure the terminal and wire within the jaws set to your required size. Use the ergonomic rubber grip handle to apply manual pressure, allowing the hardened alloy steel jaws to make a clean crimp. Always engage the integrated safety lock when the tool is not in use to prevent accidental operation.Q: What applications is this crimping machine suitable for?

A: This hand crimper is ideal for automotive, electrical, construction, and general maintenance tasks. It is designed for crimping terminals, lugs, and connectors in situations where precise and reliable connections are essential.Q: Where should I store the crimping machine when not in use?

A: Store the crimping machine in a compact toolbox or on a protected shelf to keep it free from moisture and dust. Its size and rectangular base with lever mechanism allow for easy storage and safe transport between job sites.Q: When does the machine need maintenance and what is the process?

A: Maintenance should be performed periodically, particularly after frequent use or exposure to dusty environments. Clean the jaws and moving parts, and apply manual lubrication to all moving joints to keep the mechanism functioning smoothly and extend tool life.Q: What are the benefits of using a hand-operated, manual crimping machine?

A: Manual operation offers complete control over crimping pressure, resulting in precise and consistent crimps. The machine's portability, low noise output, and ergonomic design make it user-friendly, while its durable build ensures a long service life.Q: How is the jaw material advantageous for heavy-duty use?

A: The jaws are made from hardened alloy steel, providing superior strength and wear resistance. This ensures high performance and long-lasting sharpness, even with frequent use on different terminal sizes and materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

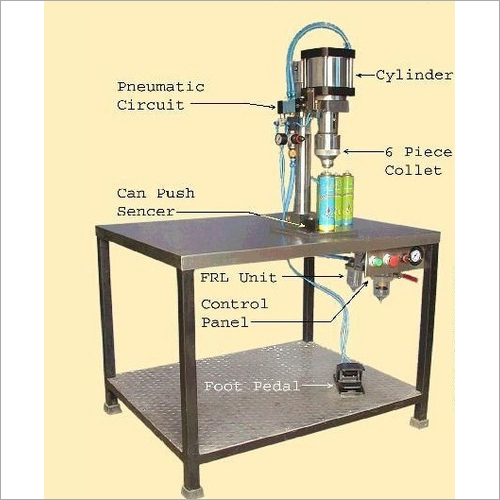

More Products in Aerosol Crimping Machine Category

Semi Automatic Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Drive Type : Belt Drive

Technology : Other, SemiAutomatic

Lubricating System : Manual Lubrication

Noise Level : Low Noise (<70 dB)

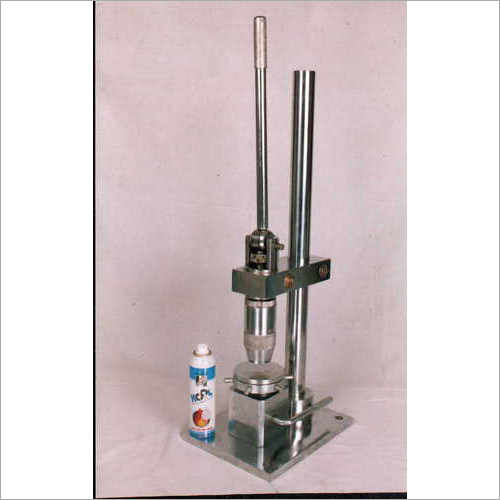

Crimping Machine (Hand Operated-Bottle)

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Drive Type : Manual Lever Drive

Technology : Other, Mechanical Lever Mechanism

Lubricating System : Manual Oil Application

Noise Level : Low

Aerosol Can Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Drive Type : Electric Motor

Technology : Other, Manual / Pneumatic Crimping

Lubricating System : Automatic

Noise Level : <75 dB

Semi Automatic Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Drive Type : Belt Driven

Technology : Other, Semi Automatic

Lubricating System : Manual Grease Lubrication

Noise Level : 70 dB

Send Inquiry

Send Inquiry