Semi Automatic Crimping Machine

Semi Automatic Crimping Machine Specification

- Surface Finish

- Smooth Painted

- Features

- Foot pedal operation, interchangeable dies, overload protection

- Noise Level

- Low Noise (<70 dB)

- Lubricating System

- Manual Lubrication

- Shape

- Rectangular base with integrated controls

- Motor Power

- 220W AC Motor

- Drive Type

- Belt Drive

- Size

- Medium

- Diameter

- Suitable for 0.56 mm wires

- Usage & Applications

- Wire terminal crimping, cable lugs, electronic industry, automotive wires

- Capacity

- Up to 3000 terminal/hour

- Product Type

- Semi Automatic Crimping Machine

- Material

- Mild Steel & Alloy

- Technology

- Semi-Automatic

- Power Source

- Electric

- Power

- 220W

- Voltage

- 220V

- Pressure

- Standard pneumatic pressure

- Surface Treatment

- Powder Coated

- Dimension (L*W*H)

- 550 x 350 x 420 mm

- Weight

- 35 kg

- Color

- Blue & Grey

- Changeover Time

- Quick change die system

- Control System

- Simple Control Panel

- Operating Speed

- Up to 3000 cycles/hour

- Operation Mode

- Foot Pedal Start

- Applicable Terminal Type

- Open barrel, closed barrel, insulated and non-insulated terminals

- Safety Features

- Safety Guard and Overload Protection

- Stroke

- 30 mm

- Die Set

- Interchangeable

- Display

- LED Indicator

- Crimping Force

- 2 Ton

- Maintenance

- Low and Easy Maintenance

Semi Automatic Crimping Machine Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 6 Week

About Semi Automatic Crimping Machine

Distinctive Performance & Versatile Applications

Designed for wire terminal and cable lug crimping, the Semi Automatic Crimping Machine excels in applications involving electronic assemblies and automotive wiring. Its quick-change die mechanism and powerful motor deliver competitive advantagesminimizing downtime and ensuring precise results across 0.56 mm wires. The foot pedal operation and interchangeable dies further enhance efficiency, making it an optimal choice for manufacturers seeking productivity without compromising on quality.

Certifications, Handover Process & Quick Dispatch

This crimping machine comes certified for reliable, industrial-grade performance and undergoes thorough quality checks before sale. We ensure handover occurs smoothly, with each unit ready at a compelling sale price. Customers benefit from our commitment to prompt deliverymachines are dispatched quickly following order confirmation. The standard FOB port is located in India, ensuring hassle-free logistics and swift turnaround for both local and global clients.

FAQs of Semi Automatic Crimping Machine:

Q: How does the quick-change die system benefit users during operation?

A: The quick-change die system allows users to switch between different terminal types rapidly, reducing downtime and increasing overall productivity during high-volume operations.Q: What safety features are integrated in this crimping machine?

A: This machine includes a safety guard and overload protection, ensuring operator safety and preventing mechanical damage during the crimping process.Q: When is the ideal application for this Semi Automatic Crimping Machine?

A: It is best utilized for wire terminal crimping, cable lugs, and connecting wires in electronic manufacturing and automotive assembly lines.Q: Where can this machine be efficiently deployed?

A: The crimping machine is suited for electronic factories, automotive workshops, and any facility requiring bulk wire terminal processing.Q: What maintenance is required to keep this machine running smoothly?

A: Thanks to its robust construction, the machine needs only low and easy maintenance, primarily involving simple, manual lubrication at regular intervals.Q: How does the foot pedal operation improve user experience?

A: The foot pedal operation allows for hands-free control, making the crimping process more ergonomic, efficient, and safe for the operator.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aerosol Crimping Machine Category

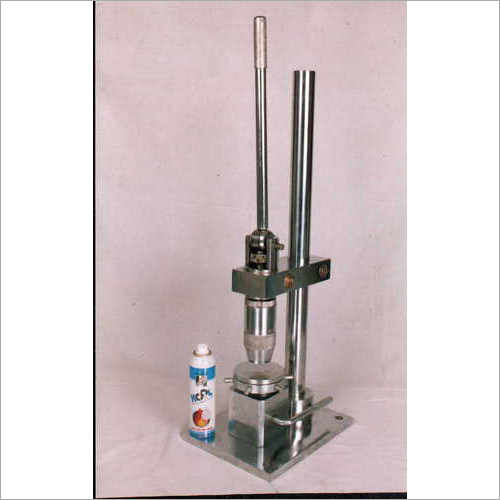

Hand Operated Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Noise Level : Low

Lubricating System : Manual lubrication required

Product Type : Other, Hand Operated Crimping Machine

Technology : Other, Manual Mechanical Operation

Crimping Machine (Hand Operated-Bottle)

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Noise Level : Low

Lubricating System : Manual Oil Application

Product Type : Other, Hand Operated Bottle Crimping Machine

Technology : Other, Mechanical Lever Mechanism

Semi Automatic Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Noise Level : 70 dB

Lubricating System : Manual Grease Lubrication

Product Type : Other, Semi Automatic Crimping Machine

Technology : Other, Semi Automatic

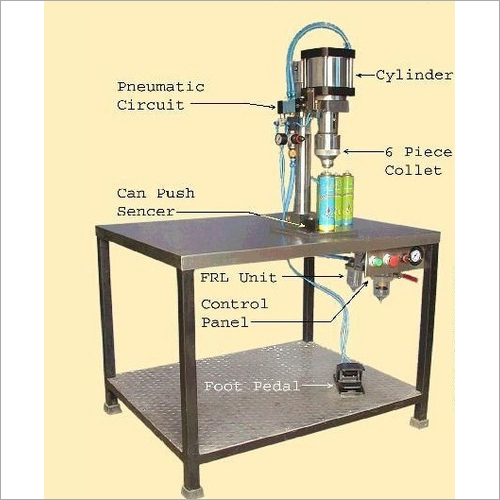

Aerosol Can Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Noise Level : <75 dB

Lubricating System : Automatic

Product Type : Other, Aerosol Can Crimping Machine

Technology : Other, Manual / Pneumatic Crimping

Send Inquiry

Send Inquiry