Aerosol De Crimping Machine

Aerosol De Crimping Machine Specification

- Lubricating System

- Manual Lubrication

- Size

- Standard

- Surface Finish

- Glossy

- Features

- Portable, Easy to Use, Precision Engineering

- Motor Power

- Not Required

- Drive Type

- Hand Operated

- Noise Level

- Low

- Capacity

- Single Can Operation

- Diameter

- Suitable for 1 Standard Aerosol Can Neck

- Product Type

- Aerosol De Crimping Machine

- Material

- Stainless Steel

- Technology

- Precision Crimping Mechanism

- Power Source

- Manual

- Pressure

- Manual Pressure Operated

- Surface Treatment

- Polished Finish

- Dimension (L*W*H)

- Approx. 250 x 120 x 320 mm

- Color

- Metallic Silver

Aerosol De Crimping Machine Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 6 Week

- Main Domestic Market

- All India

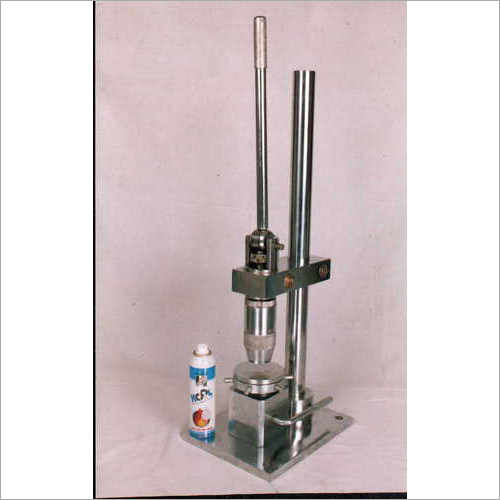

About Aerosol De Crimping Machine

Our modern infrastructure unit and immense market know how enables us to manufacture, supply and export Aerosol De Crimping Machine. Made of superlative quality raw materials and parts, these products provide accurate and optimum operations. With longer service life corrosion free surface and less maintenance, these products have earned the trust of the clients. Aerosol De Crimping Machine is paced in special packaging material in order to ensure their safe transportation.

Engineered for Portability and Ease of Use

This machine is designed with portability in mind, making it easy to transport and set up anywhere your operation requires. Its simple hand-operated mechanism ensures that users can quickly master its functionality, making the de-crimping process straightforward and efficient for a variety of aerosol cans.

Precision and Durability Combined

Crafted with precision engineering, the machine guarantees accurate de-crimping every time. The stainless steel construction ensures long-lasting resilience, while the polished and glossy surface finish maintains a clean, professional look, even in rigorous industrial environments.

FAQs of Aerosol De Crimping Machine:

Q: How do I operate the Aerosol De Crimping Machine?

A: The machine is hand-operatedsimply position the standard aerosol can neck into the de-crimping area, apply manual pressure to the lever, and the precision mechanism will safely remove the crimp for you.Q: What benefits does the manual operation provide?

A: Manual operation eliminates the need for an external power source or motor, making the machine more portable and suitable for locations without electricity, while also keeping noise to a minimum.Q: Where can this machine be used effectively?

A: Its portable design and robust construction make it ideal for use in manufacturing facilities, laboratories, recycling units, and on-site industrial applications across India.Q: When does the machine require lubrication?

A: Lubrication should be performed manually at regular intervals, especially following extended periods of use, to maintain smooth operation and extend the machines lifespan.Q: What can size and can neck diameter is the machine compatible with?

A: It is designed for single-can operations and fits the standard aerosol can neck diameter, ensuring a secure fit and precise de-crimping every time.Q: What maintenance process should be followed for longevity?

A: Routine cleaning, regular manual lubrication, and periodic inspection of moving parts ensure the device remains in optimal working condition.Q: What are the main benefits of using this Aerosol De Crimping Machine?

A: Users benefit from its precision engineering, easy manual operation, low noise level, and robust stainless steel construction, resulting in efficient and safe de-crimping with minimal fuss.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aerosol Crimping Machine Category

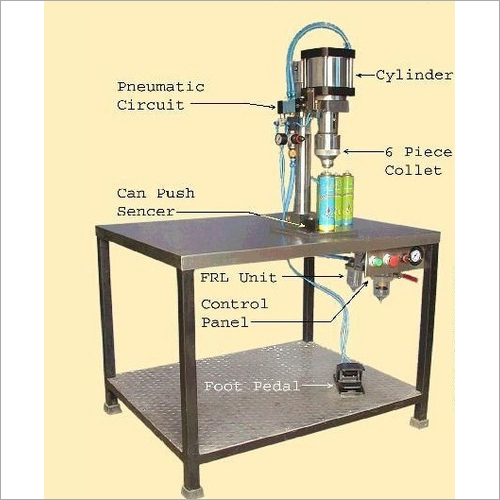

Semi Automatic Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Drive Type : Belt Drive

Surface Treatment : Other, Powder Coated

Color : Blue & Grey

Shape : Rectangular base with integrated controls

Crimping Machine (Hand Operated-Bottle)

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Drive Type : Manual Lever Drive

Surface Treatment : Other, Polished/Coated

Color : Silver/Grey

Shape : Rectangular Base with Tapered Lever Handle

Hand Operated Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Drive Type : Hand Operated

Surface Treatment : Other, Powder Coated

Color : Blue & Silver

Shape : Rectangular Base with Lever Mechanism

Aerosol Can Crimping Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Drive Type : Electric Motor

Surface Treatment : Other, Polished

Color : Silver

Shape : Vertical

Send Inquiry

Send Inquiry