ठरà¥à¤§-सà¥à¤µà¤¯à¤à¤à¤²à¤¿à¤¤ à¤à¥ स

ठरà¥à¤§-सà¥à¤µà¤¯à¤à¤à¤²à¤¿à¤¤ à¤à¥ स Specification

- अचूकता

- ±0.2%

- फ्रेम प्रकार

- Heavy Duty Mild Steel

- ऑपरेटिंग तापमान

- 5°C to 40°C

- मशीन प्रकार

- Filling Machine

- व्होल्टेज

- 220V/380V

- ड्राइव्ह

- Electric Motor

- मोटर पॉवर

- 1 HP

- कूलिंग सिस्टम

- Air Cooling

- कनेक्टिव्हिटी पर्याय

- Standard

- वारंवारता

- 50 Hz

- नियंत्रण प्रणाली

- वंगण प्रणाली

- Automatic Oil Lubrication

- ध्वनी पातळी

- <70 dB

- पॉवर रेटिंग

- 1.5 kW

- उत्पादनाचा प्रकार

- उर्जा स्त्रोत

- पॉवर

- 1.5 kW

- पृष्ठभाग उपचार

- आकारमान (एल* प* एच)

- 1200 mm x 800 mm x 1850 mm

- वजन (किलो)

- ~220 Kg

- रंग

- Blue / Grey

- वापर/अनुप्रयोग

- Filling of Various Industrial & Domestic Gas Cylinders

ठरà¥à¤§-सà¥à¤µà¤¯à¤à¤à¤²à¤¿à¤¤ à¤à¥ स Trade Information

- Minimum Order Quantity

- 01 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- आठवडा

- मुख्य देशांतर्गत बाजार

- संपूर्ण भारत

About ठरà¥à¤§-सà¥à¤µà¤¯à¤à¤à¤²à¤¿à¤¤ à¤à¥ स

We have been able to meet all the requirements of our esteemed patrons by manufacturing, supplying and exporting Manual Aerosol Filling Machine. Made of high grade raw materials , these products provide precise and accurate aerosol filling solutions. With continuous flow, these products help in increasing the production. The flow of these machines can be regulated owing to their manual operations. Manual Aerosol Filling Machine is delivered to the clients in an quick manner owing to our expert delivery team.

Features:

- Simple & quick in operation.

- Adjustable as per can size.

- Efficiency: 25 to 30 valves per minute.

- Negligible compress air consumption.

Precision and Versatility in Gas Filling

Engineered for a range of gases such as LPG, Ammonia, CO2, and Nitrogen, this machine supports all standard gas cylinders. Its adjustable filling range caters to both small and large demands, from 1 kg up to 100 kg per cycle. This versatility makes it suitable for various industries, including manufacturing plants, commercial suppliers, and service providers.

Robust Safety Features and Digital Control

Safety is paramount in gas handling, and this machine incorporates essential mechanisms like an emergency stop button and advanced leak detection sensors. The digital controller, weight display, and high-precision pressure gauge ensure real-time monitoring and maximum operational integrity during every fill.

Efficient, Reliable, and User-Friendly Operation

Designed for minimal energy consumption while maintaining top-level accuracy, the semi-automatic gas filling machine employs a digital calibration system and automatic oil lubrication for smooth operation. Its batch counter and low-noise performance further contribute to an efficient and user-friendly experience.

FAQs of Semi Automatic GAS Filling Machine:

Q: How does the semi automatic gas filling machine ensure safety during operation?

A: The machine is equipped with multiple safety features, including an emergency stop mechanism and leak detection sensors. These systems help prevent accidents by allowing operators to halt the process instantly and by detecting any gas leaks during filling.Q: What types of gases can this filling machine handle?

A: This machine is compatible with LPG, Ammonia, CO2, Nitrogen, and a variety of other industrial gases, making it suitable for a broad scope of applications.Q: When should digital calibration be performed on the gas filling machine?

A: Digital calibration should be conducted regularly as recommended in the user manualtypically before starting a new batch or after a set period of operationto maintain measurement accuracy within the specified 0.2% range.Q: Where can this filling machine be utilized?

A: The machine is designed for use in industrial settings, gas bottling plants, and commercial supply facilities. It is also suitable for servicing both industrial and domestic gas cylinders due to its flexible filling range and compatibility.Q: What is the process for filling a cylinder using this machine?

A: Place the cylinder on the designated platform and connect it securely. Select the desired filling weight using the digital display, and start the process. The machine automatically fills the cylinder, monitors weight digitally, and features an emergency stop in case immediate shutdown is necessary.Q: What are the main benefits of using this semi automatic gas filling machine?

A: Key advantages include high accuracy (0.2%), robust safety features, compatibility with multiple gases and cylinder types, digital monitoring, low energy consumption, and durable construction for long-term reliability.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Aerosol Deep Tube Cutting Machine Category

एरोसोल कॅन फिलिंग मशीन

मापनाचे एकक : तुकडा/तुकडे

किमान ऑर्डरची मात्रा : 01

किंमत किंवा किंमत श्रेणी : INR

नियंत्रण प्रणाली : ,

किंमत एकक : तुकडा/तुकडे

उर्जा स्त्रोत : ,

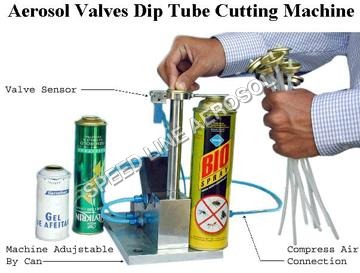

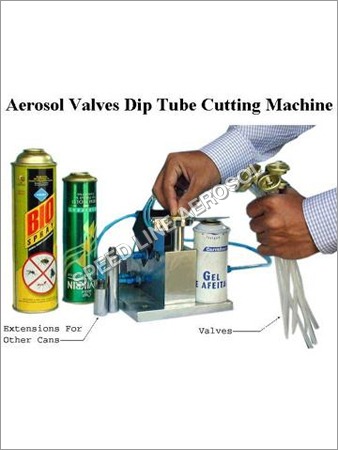

डिपट्यूब कटिंग मशीन

मापनाचे एकक : तुकडा/तुकडे

किमान ऑर्डरची मात्रा : 01

किंमत किंवा किंमत श्रेणी : INR

नियंत्रण प्रणाली : ,

किंमत एकक : तुकडा/तुकडे

उर्जा स्त्रोत : ,

एरोसोल ट्यूब कटिंग मशीन

मापनाचे एकक : तुकडा/तुकडे

किमान ऑर्डरची मात्रा : 1

किंमत किंवा किंमत श्रेणी : INR

नियंत्रण प्रणाली : SemiAutomatic

किंमत एकक : तुकडा/तुकडे

उर्जा स्त्रोत : Electricity

चौकशी पाठवा

चौकशी पाठवा