डिपà¤à¥à¤¯à¥à¤¬ à¤à¤à¤¿à¤à¤ मशà¥à¤¨

डिपà¤à¥à¤¯à¥à¤¬ à¤à¤à¤¿à¤à¤ मशà¥à¤¨ Specification

- फ्रेम प्रकार

- Heavy Duty Mild Steel Frame

- व्होल्टेज

- 220V

- नियंत्रण प्रणाली

- मशीन प्रकार

- Tube Cutting Machine

- पॉवर रेटिंग

- 220 V / 50 Hz

- कनेक्टिव्हिटी पर्याय

- Standard RS232 Interface

- ध्वनी पातळी

- Below 70 dB

- कूलिंग सिस्टम

- Air Cooling

- वारंवारता

- 50 Hz

- प्लॅस्टिक प्रक्रिया

- PE, PP, PVC

- कार्यरत आहे गती

- Adjustable, up to 110 cycles/min

- मोटर पॉवर

- 1 HP

- ड्राइव्ह

- Servo Motor Drive

- वैशिष्ट्ये

- Digital length setting, high precision, safety guards, automatic feed

- वंगण प्रणाली

- Automatic Grease Type

- उत्पादन क्षमता

- Up to 5000 pieces/hour

- उत्पादनाचा प्रकार

- तंत्रज्ञान

- उर्जा स्त्रोत

- पॉवर

- 1.5 kW

- पृष्ठभाग उपचार

- आकारमान (एल* प* एच)

- 1100 x 700 x 1200 mm

- वजन (किलो)

- 160 kg

- वापर/अनुप्रयोग

- Precise cutting of diptubes for packaging, cosmetic, and pharma industries

डिपà¤à¥à¤¯à¥à¤¬ à¤à¤à¤¿à¤à¤ मशà¥à¤¨ Trade Information

- Minimum Order Quantity

- 01 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- आठवडा

- मुख्य देशांतर्गत बाजार

- संपूर्ण भारत

About डिपà¤à¥à¤¯à¥à¤¬ à¤à¤à¤¿à¤à¤ मशà¥à¤¨

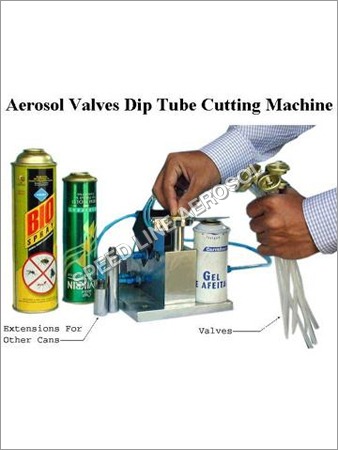

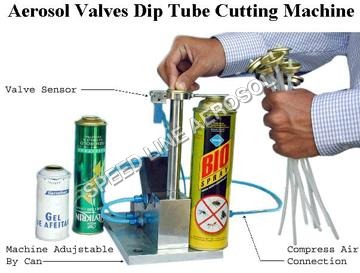

We have acquired considerable reputation in the industry as the manufacturers, suppliers and exporters of Diptube Cutting Machines. Premium quality raw materials and components have been obtained from the certified sellers of the market for engineering these products. With high productivity and smooth operations, these machines have a high popularity in the international market. Diptube Cutting Machines is known in the market for its corrosion less surface and less wear & tear.

Specifications:

-

Simple & quick in operation.

-

Adjustable as per can size.

-

Efficiency: 25 to 30 valves per minute.

-

Negligible compress air consumption.

Effortless Precision and Flexibility

This machine delivers reliable and consistent tube cutting across a wide range of plastic materials, including PE, PP, and PVC. The digital length setting and adjustable speed ensure each diptube is manufactured to exact specifications, meeting the demanding needs of pharmaceutical, cosmetic, and packaging sectors. The automatic feed and servo motor drive boost productivity and reduce manual intervention.

Advanced User Interface and Controls

Operating the Diptube Cutting Machine is straightforward thanks to its PLC-controlled system and touch screen HMI. The intuitive interface enables quick adjustments of cutting length, speed, and other parameters, making it easy for operators to switch between jobs, track production status, and access diagnostics for minimal downtime.

Safety and Maintenance Made Simple

With integrated emergency stop, overload protection, and safety guards, this machine prioritizes operator safety at all times. Routine maintenance is minimal due to the automatic grease-type lubrication system and easily replaceable components, helping manufacturers achieve longer machine lifespans with less effort.

FAQs of Diptube Cutting Machine:

Q: How does the Diptube Cutting Machine ensure precise cutting for various tube materials?

A: The machine employs a high-precision servo motor drive and digital length control, allowing exact cuts for both soft and rigid plastic tubes, such as PE, PP, and PVC. Adjustments for tube length and diameter are easily made through the touch screen HMI for consistently accurate results.Q: What safety features are included in this tube cutting machine?

A: It is equipped with an emergency stop function, overload protection, and safety guards, ensuring safe operation for users. The safety system responds immediately to hazards, complying with CE standards for operator protection.Q: When is maintenance required, and how easy is it to perform?

A: Routine maintenance needs are low, thanks to the automatic grease lubrication and robust design. Components that typically need replacement are straightforward to access and switch, minimizing downtime and making upkeep efficient for operators.Q: Where is the Diptube Cutting Machine most commonly used?

A: This machine is ideal for industries like packaging, cosmetics, and pharmaceuticals, where precise diptube cutting is essential for product quality and packaging processes.Q: What is the operating process for setting tube cutting length?

A: Tube cutting length is set digitally via the touch screen HMI. Operators simply enter the desired measurement, and the system adjusts automatically, supporting tube lengths from 30 mm to 600 mm.Q: How does the machines production capacity benefit manufacturers?

A: With a maximum speed of 110 cycles per minute and capacity of up to 5,000 pieces per hour, manufacturers can achieve rapid throughput and meet high-volume order demands efficiently.Q: What are the power requirements and environmental limitations for installation?

A: The machine operates on 220V, 50Hz power and consumes approximately 1.5 units per hour. It is best used in environments with ambient humidity at or below 85% RH to ensure optimal performance and longevity.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Aerosol Deep Tube Cutting Machine Category

एरोसोल कॅन फिलिंग मशीन

किमान ऑर्डरची मात्रा : 01

किंमत एकक : तुकडा/तुकडे

उत्पादनाचा प्रकार : ,

उर्जा स्त्रोत : ,

वापर/अनुप्रयोग : Filling aerosol cans for deodorants, air fresheners, and similar products

नियंत्रण प्रणाली : ,

अर्ध-स्वयंचलित गॅस

किमान ऑर्डरची मात्रा : 01

किंमत एकक : तुकडा/तुकडे

उत्पादनाचा प्रकार : ,

उर्जा स्त्रोत : ,

वापर/अनुप्रयोग : Filling of Various Industrial & Domestic Gas Cylinders

नियंत्रण प्रणाली : ,

एरोसोल ट्यूब कटिंग मशीन

किमान ऑर्डरची मात्रा : 1

किंमत एकक : तुकडा/तुकडे

उत्पादनाचा प्रकार : ,

उर्जा स्त्रोत : Electricity

वापर/अनुप्रयोग : Industrial

नियंत्रण प्रणाली : SemiAutomatic

चौकशी पाठवा

चौकशी पाठवा