à¤à¥à¤¸à¥à¤®à¥à¤à¤¿à¤ à¤à¤°à¤£à¥à¤¯à¤¾à¤à¥

à¤à¥à¤¸à¥à¤®à¥à¤à¤¿à¤ à¤à¤°à¤£à¥à¤¯à¤¾à¤à¥ Specification

- उत्पादनाचा प्रकार

- Cosmetic Filling Equipment

- साहित्य

- Stainless Steel

- अनुप्रयोग

- पॅकेजिंग साहित्य

- संगणकीकृत

- स्वयंचलित ग्रेड

- नियंत्रण प्रणाली

- ड्राइव्ह प्रकार

- व्होल्टेज

- 220V/50Hz

- वजन (किलो)

- 350 kg

- आकारमान (एल* प* एच)

- 2200 x 900 x 1650 mm

- वैशिष्ट्य

- रंग

à¤à¥à¤¸à¥à¤®à¥à¤à¤¿à¤ à¤à¤°à¤£à¥à¤¯à¤¾à¤à¥ Trade Information

- Minimum Order Quantity

- 01 तुकडा

- पुरवठा क्षमता

- प्रति महिना

- वितरण वेळ

- आठवडा

- मुख्य देशांतर्गत बाजार

- संपूर्ण भारत

About à¤à¥à¤¸à¥à¤®à¥à¤à¤¿à¤ à¤à¤°à¤£à¥à¤¯à¤¾à¤à¥

With persistent and diligent efforts to maintain the standards of the market, we are able to manufacture, supply and export Cosmetic Filling Equipment. Used for filling of bottles and tunes, these products find application in the cosmetics industry. Our clients acknowledge these products for their effective operation and durable nature. Cosmetic Filling Equipment is packed in special bubble material in order to ascertain its damage free transit at the clients premises.

Unmatched Filling Versatility

Suitable for everything from low to high viscosity liquids, this piston-type volumetric filling equipment adapts seamlessly to a diverse range of cosmetic, pharmaceutical, and chemical products. Its four adjustable filling heads combined with an automatic PLC control system provide precise and efficient liquid dispensing.

Efficient and Automated Operation

With fully automated operation, the filling process becomes straightforward and efficient. The easy-to-use PLC interface, computerized controls, and electric drive ensure optimal speed and consistent accuracy, while the large 60-liter hopper minimizes downtime for refills.

Built for Durability and Hygiene

Constructed from premium stainless steel, this equipment resists corrosion and is easy to clean, making it ideal for hygiene-critical industries. Its robust build ensures longevity and reliable performance in demanding environments, supporting both small and large-scale operations.

FAQs of Cosmetic Filling Equipment:

Q: How does the equipment achieve high filling accuracy for different liquid viscosities?

A: The machine uses a piston-type volumetric filling principle, which precisely measures and dispenses liquids. This, along with four synchronized filling heads and a PLC control system, ensures consistent and accurate fills for both low and high viscosity products.Q: What is the process for adjusting the conveyor speed during filling operations?

A: The conveyor speed is easily adjustable via the user-friendly control panel. Operators can tailor the speed to match product type and packaging requirements, ensuring optimal flow and minimal spillage during operation.Q: When should the hopper be refilled, and what is its capacity?

A: The hopper has a 60-liter capacity, allowing extended filling times for medium to large production runs. It should be refilled when the remaining product approaches the minimum working level, as indicated by the integrated sensors or visual level markers.Q: Where can this filling equipment be installed and operated?

A: This equipment is suitable for installation in cosmetic, pharmaceutical, or chemical manufacturing facilities. Its compact footprint (2200 x 900 x 1650 mm) and quiet operation make it adaptable to various production environments, whether on a dedicated filling line or as part of a modular system.Q: What packaging materials and container types are compatible with this equipment?

A: The equipment is designed to fill both plastic and glass containers of varying shapes and sizes, providing versatility across different product lines. The robust mechanism handles a range of viscosities without sacrificing accuracy.Q: How does the PLC control system benefit overall usage and productivity?

A: The integrated PLC control system automates filling parameters, improves consistency, and allows easy adjustments. This reduces operator workload, increases productivity, and ensures each fill meets precise volume requirements.Q: What are the main benefits of using this automatic cosmetic filling machine?

A: Key benefits include high filling accuracy, easy operation, low noise output, and reduced labor requirements. Its stainless steel construction ensures durability and hygiene, while automation boosts efficiency and minimizes downtime.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in Aerosol Filling Machine Category

एरोसोल भरणे उपकरणे

किंमत किंवा किंमत श्रेणी : INR

किमान ऑर्डरची मात्रा : 01

मापनाचे एकक : तुकडा/तुकडे

साहित्य : Stainless Steel

संगणकीकृत : No

आकारमान (एल* प* एच) : 900mm x 500mm x 1500mm

एरोसोल गॅस भरणे मशीन

किंमत किंवा किंमत श्रेणी : INR

किमान ऑर्डरची मात्रा : 01

मापनाचे एकक : तुकडा/तुकडे

साहित्य : Stainless Steel

संगणकीकृत : No

आकारमान (एल* प* एच) : 900 x 700 x 1600 mm

रोटरी भरणे मशीन

किंमत किंवा किंमत श्रेणी : INR

किमान ऑर्डरची मात्रा : 01

मापनाचे एकक : तुकडा/तुकडे

साहित्य : Stainless Steel (SUS 304/316)

संगणकीकृत : Yes

आकारमान (एल* प* एच) : 1800 mm x 1200 mm x 2200 mm

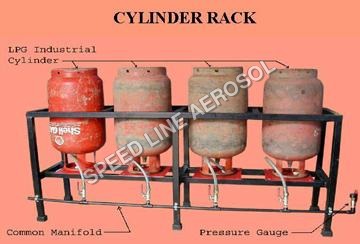

गॅस सिलेंडर स्टोरेज रॅक

किंमत किंवा किंमत श्रेणी : INR

किमान ऑर्डरची मात्रा : 01

मापनाचे एकक : तुकडा/तुकडे

साहित्य : Mild Steel (MS) with powder coated finish

संगणकीकृत : No

आकारमान (एल* प* एच) : 1200 mm x 600 mm x 1500 mm (customizable)

चौकशी पाठवा

चौकशी पाठवा