CO2 GAS Filling Machine

CO2 GAS Filling Machine Specification

- Product Type

- CO2 Gas Filling Machine

- Material

- Mild Steel Body with Stainless Steel Accessories

- Application

- Industrial CO2 Cylinder Filling

- Packaging Material

- Wooden Box

- Computerized

- Yes

- Control System

- PLC Based

- Drive Type

- Electric Motor

- Weight (kg)

- 300 kg

- Dimension (L*W*H)

- 1200 x 800 x 1600 mm

- Feature

- High Fill Accuracy, Safety Interlocks, Easy Operation

- Color

- Blue & Grey

- Filling Pressure Range

- Up to 200 Bar

- Operation Mode

- Manual/Automatic

- No. of Filling Heads

- Single

- Cylinder Type Supported

- All Standard CO2 Cylinders

- Power Consumption

- 2.5 kW

- Working Temperature Range

- 5°C to 45°C

- Display Type

- Digital/LED Weight Display

- Filling Accuracy

- ±0.2% of Full Scale

- Noise Level

- <75 dB

- Safety Features

- Inbuilt Emergency Stop, Pressure Relief Valve

CO2 GAS Filling Machine Trade Information

- Minimum Order Quantity

- 01 Piece

- Supply Ability

- 25 Pieces Per Month

- Delivery Time

- 6 Week

- Main Domestic Market

- All India

About CO2 GAS Filling Machine

With our innovative production facilities, we are able to manufacture, supply and export Flexible Aerosol Filling Machine. These products are used in different chemical and pharmaceutical industries. Known for their effective performance, these products are very popular among our respected clients in the international market. These products are duly checked by our team of proficient quality team to ensure their defect free operation. Flexible Aerosol Filling Machine is delivered to the clients in a designated time frame owing to our expert carriage and freight personnel.

Precision and Reliability

Achieve consistently accurate CO2 fillings with a high fill accuracy of 0.2% of full scale. The integrated digital/LED weight display provides real-time verification, minimizing errors and ensuring every cylinder is filled precisely to specification without overfilling.

Safety First Operation

This machine is equipped with critical safety features such as an inbuilt emergency stop, pressure relief valve, and multiple safety interlocks. These measures protect both operators and equipment, making it suitable for demanding industrial environments that prioritize operational security.

Versatile Application

Designed for adaptability, the CO2 Gas Filling Machine supports all standard CO2 cylinder types. Its dual manual/automatic operation modes and PLC-based controls allow easy and flexible use across various industrial gas filling applications throughout India.

FAQs of CO2 GAS Filling Machine:

Q: How does the CO2 Gas Filling Machine ensure precise cylinder filling?

A: The machine delivers high precision with a digital/LED weight display and a fill accuracy of 0.2% of full scale, assisted by PLC-based controls. This allows for reliable, consistent filling of CO2 cylinders to exact specifications.Q: What safety features are incorporated in the CO2 Gas Filling Machine?

A: It is equipped with an inbuilt emergency stop, a pressure relief valve, and safety interlocks to protect operators and prevent overpressure. These features meet industrial safety standards for CO2 filling operations.Q: When is the ideal temperature range to operate this machine?

A: For optimal performance and longevity, operate the machine within its specified working temperature range of 5C to 45C. This ensures the equipment functions efficiently and safely.Q: Where can this CO2 filling machine be used?

A: The machine is designed for industrial use and is suitable for exporters, manufacturers, and suppliers working with standard CO2 cylinders. It is widely utilized in industrial gas plants and filling stations across India.Q: What types of CO2 cylinders are supported for filling?

A: This filling machine supports all standard CO2 cylinders, making it a flexible solution for a wide variety of industrial applications.Q: How does the machine operate and control the filling process?

A: With both manual and automatic operation modes controlled via a PLC system, the machine ensures consistent, controlled filling cycles. The digital controls and electric motor drive enhance accuracy and ease of use.Q: What are the primary benefits of using this specific CO2 Filling Machine model?

A: Key benefits include enhanced filling precision, robust safety mechanisms, adaptable operation, and a durable construction with a mild steel body and stainless steel accessories, all designed for the demanding needs of the industrial CO2 market.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aerosol Filling Machine Category

Four Head Semi Automatic Co2 Gas Filling Machine

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Dimension (L*W*H) : 1350 mm x 900 mm x 1650 mm

Material : Mild Steel with AntiCorrosive Coating

Computerized : No

Product Type : Four Head Semi Automatic CO2 Gas Filling Machine

Rotary Filling Machine

Price Range 120000.00 - 250000.00 INR

Minimum Order Quantity : 01 Piece

Dimension (L*W*H) : 1800 mm x 1200 mm x 2200 mm

Material : Stainless Steel (SUS 304/316)

Computerized : Yes

Product Type : Rotary Filling Machine

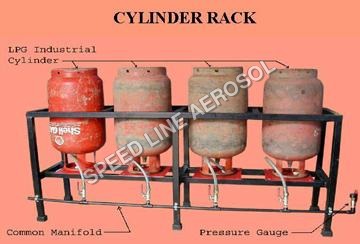

LPG Gas Cylinder Storage Rack

Price Range 120000.00 - 250000.00 INR

Minimum Order Quantity : 01 Piece

Dimension (L*W*H) : 1200 mm x 600 mm x 1500 mm (customizable)

Material : Mild Steel (MS) with powder coated finish

Computerized : No

Product Type : LPG Gas Cylinder Storage Rack

Aerosol Filling Equipment

Price Range 120000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 01 Piece

Dimension (L*W*H) : 900mm x 500mm x 1500mm

Material : Stainless Steel

Computerized : No

Product Type : Aerosol Filling Equipment

Send Inquiry

Send Inquiry